Measurements of Bismuth Absorber

Darren Dowell -- (626)395-6675 (office), -2600 (lab), 796-8806 (FAX)

Last modified Sunday, 25-Feb-2001 9:51 PST

cdd@submm.caltech.edu

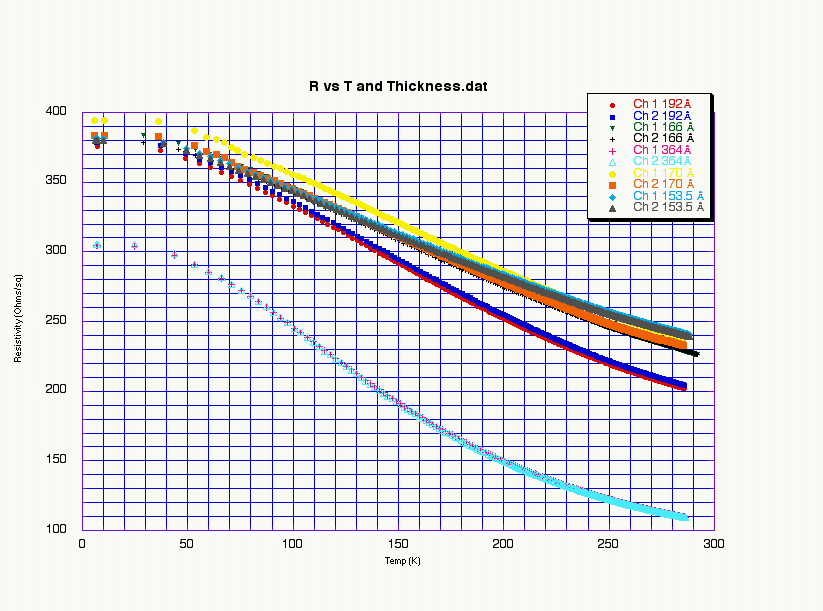

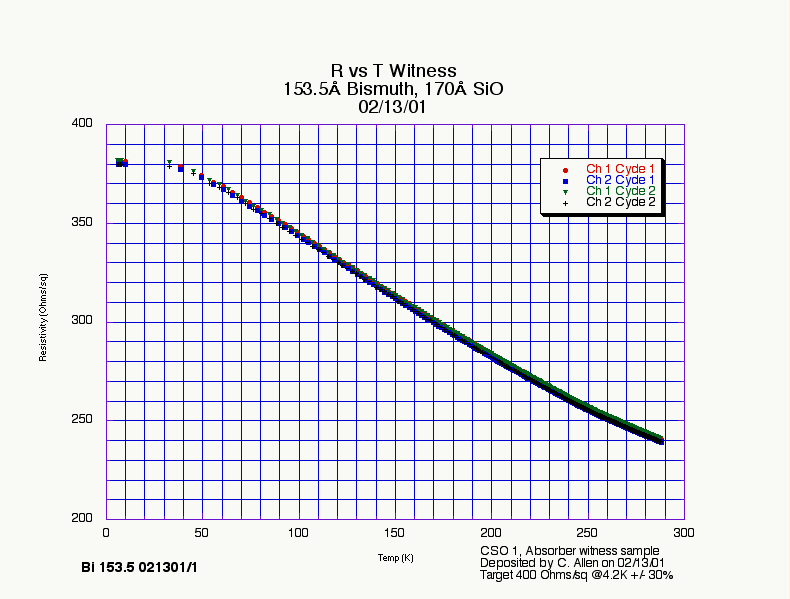

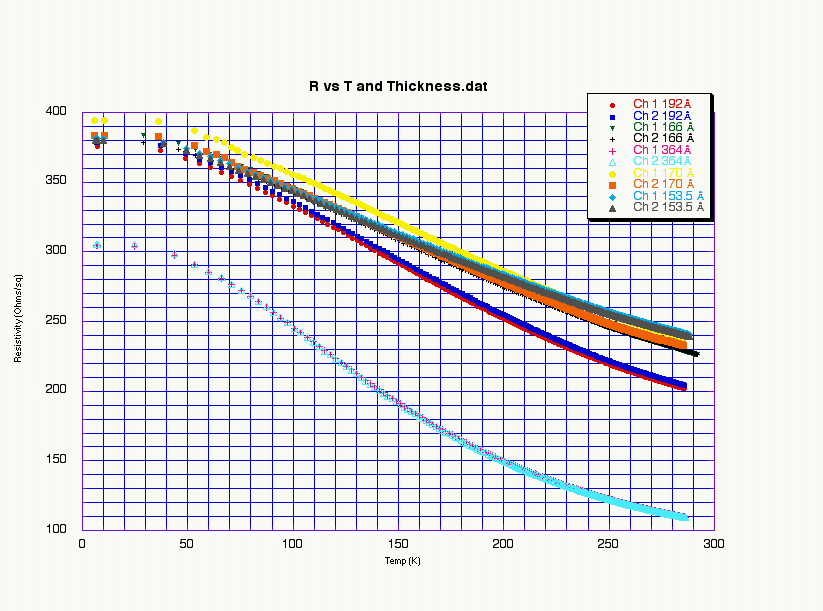

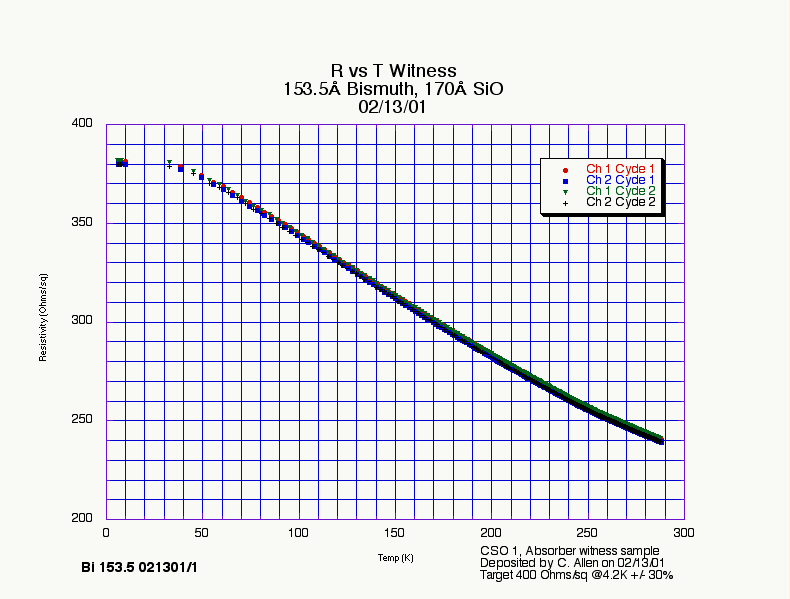

SHARC II absorber, cold DC resistance -- February 2001

Cold electrical resistance measurements of witness samples prepared and

measured by Christine Allen (GSFC) are shown below:

SHARC II absorber, FTS characterization -- February 2001

Christine Allen (GSFC) deposited 154 Angstroms bismuth and 175 Angstroms SiO

on a silicon wafer provided by Mino Freund (GSFC). Ken Stewart (GSFC) measured

the cold transmission of the coated wafer as well as an uncoated one on

February 23, 2001. The

transmission spectra were modeled using the equations of Clarke et al. (1977).

Figure 1. Cold transmission spectrum of bare wafer. The red curve

shows the

best 'by-eye' fit to the data (black dots)

using the index of refraction of silicon (n = 3.38) from Loewenstein et al.

(1973). The green curve shows the index of refraction (n=3.28) which best

fits the transmission minima. In both cases, an absorption of 1% was found.

The wafer thickness (101.5 and 104.6 microns) was treated as a free parameter

and was fit using the fringe spacing.

Figure 2. Cold transmission spectrum of coated wafer. For the

models, the

Loewenstein et al. (1973) index of refraction for silicon is used, and the

silicon absorption (1%) is the same as in Figure 1. The green, blue, and

red curves show the predictions for 300, 400, and 500 ohms/square. The

resistance which best fits the data (black dots) is approximately 430

ohms/square. The wafer thickness was fit to be 103.7 microns.

Figure 3. Cold transmission spectrum of coated wafer. For these

models, the

index of refraction (n = 3.2) was optimized to best fit the fringes. The

silicon absorption (1%) is the same as in Figure 1. The green, blue, and

red curves show the predictions for 300, 400, and 500 ohms/square. The

resistance which best fits the data (black dots) is approximately 400

ohms/square. The wafer thickness was fit to be 109.5 microns.

CONCLUSION: This bismuth deposition recipe produces 400 ohms/square DC

(electrical) on the witness sample and 400 ohms/square in the far-IR (optical)

on the FTS sample wafer. The SHARC II target resistance is 400 ohms.

THEREFORE, THE FIRST SHARC II BOLOMETER DEPOSITIONS SHOULD USE THIS ABSORBER

RECIPE.

Go to SHARC II home page...